2023 Design Fellow Liane Makatura Reimagines the Way we Design and Manufacture Physical Objects

Apr 24, 2024

Maxine Perroni-Scharf, PhD student in Electrical Engineering and Computer Science (EECS) at MIT and 2024 MAD Design Fellow, shares how her team combined real-world testing, machine learning, and micro-scale fabrication to design new metamaterial structures that outperform known materials.

By Adelaide Zollinger

Aug 10, 2025

This Q&A features 2024 MAD Design Fellow Maxine Perroni Scharf of MIT EECS, one of the lead authors of the research. The project was co-led by Zachary Ferguson (MIT EECS and CLO Virtual Fashion) and included contributions from Thomas Butruille and Carlos Portela of MIT Mechanical Engineering, and Mina Konaković Luković of MIT EECS.

Data-Efficient Discovery of Hyperelastic TPMS Metamaterials with Extreme Energy Dissipation

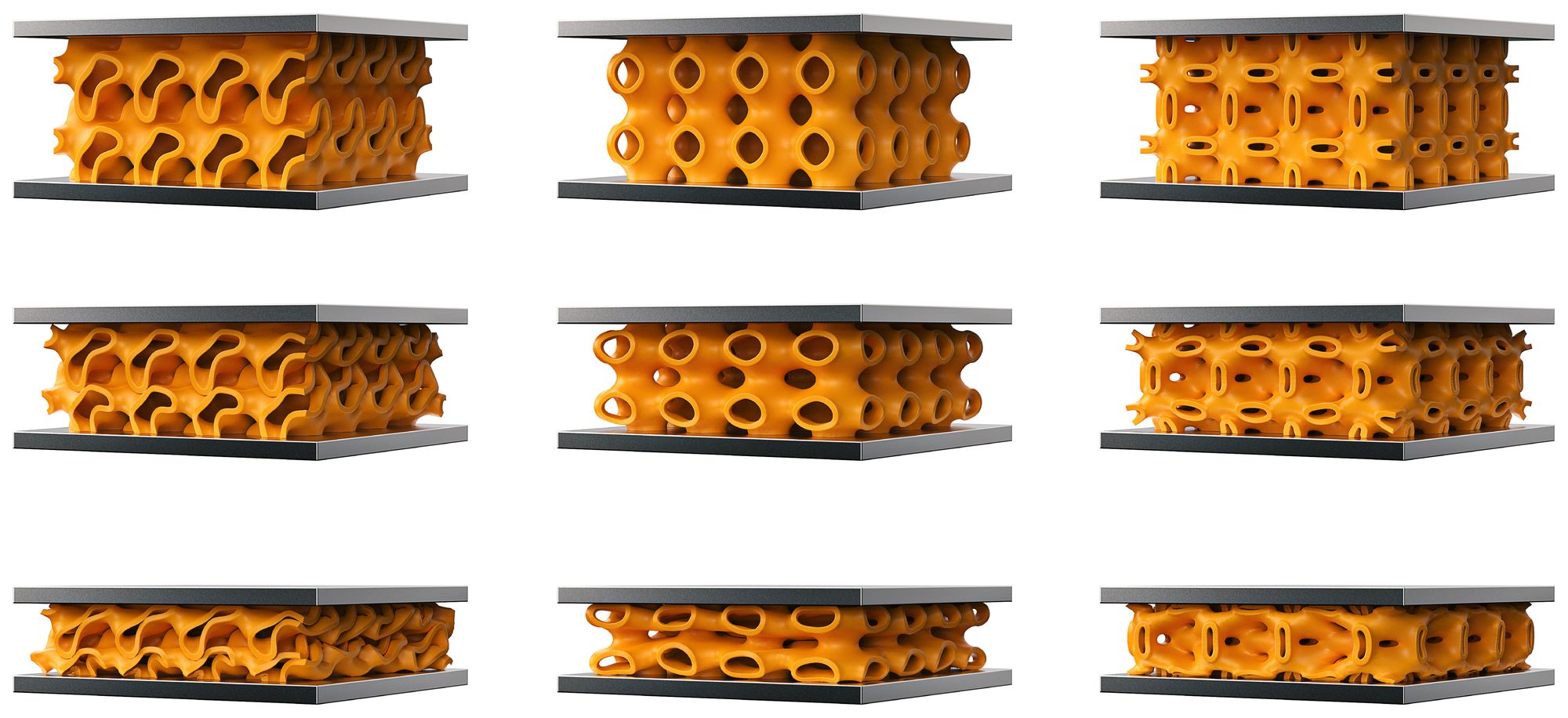

Renders of three TPMS structures being compressed. Rows present 0, 25%, and 50% compression of each structure respectively.

Image courtesy of the researchers

Q: What are triply periodic minimal surfaces (TPMS), and what does energy dissipation mean in this context? What drew you to this area of research?

A: TPMS are a class of triply-periodic mathematical surfaces with mean curvature of zero. In our work, we explore structures obtained from interpolating between eight classic TPMS primitives, which form the building blocks of our design space.

Energy dissipation is the process of energy being transferred out of a system and lost to its surroundings. I was drawn to this area of research due to my interest in leveraging machine learning principles to discover new structures that can be useful for a wide variety of applications.

Q: Your paper describes a method for discovering new TPMS metamaterials that absorb more than twice the energy of existing designs. What makes that leap possible — was it a materials insight, a modeling breakthrough, or both?

A: The leap is made possible through a combination of modeling and insights about the materials. TPMS are an already promising group of structures that have been deployed for applications where energy dissipation is important, like bone scaffolding. Our insight was to use Bayesian optimization, a technique that efficiently explores a performance space where we have sparse data points, to see if we could find structures even better than those commonly used in previous work.

Q: Simulations are a common tool in materials design, but your work leans heavily on real-world testing. Why did you choose that path, and what did you gain from it?

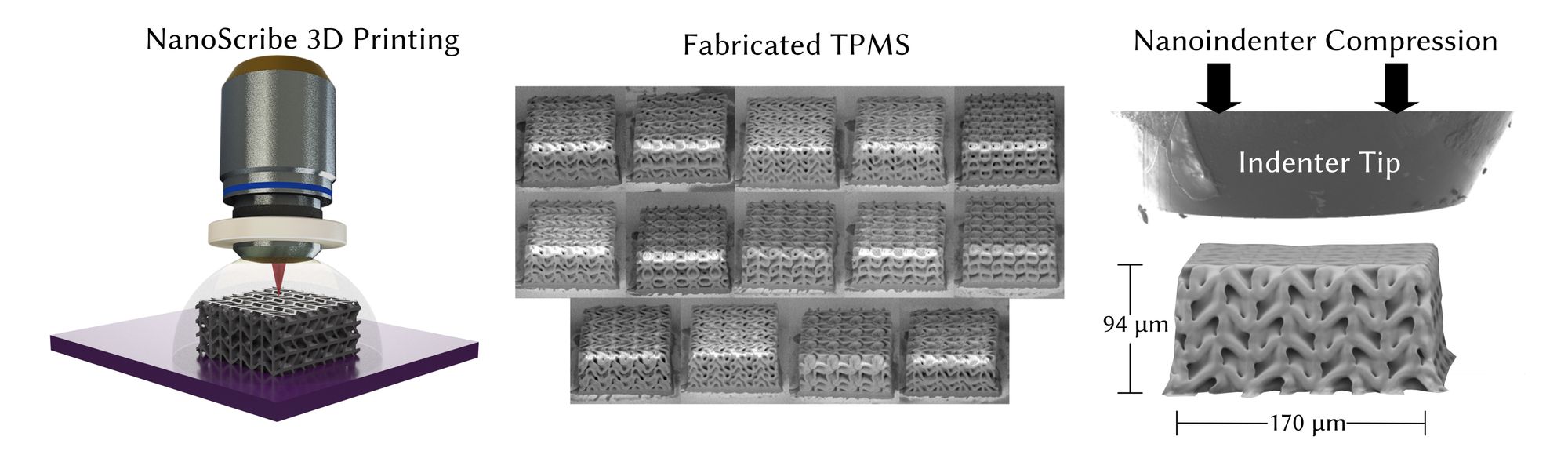

A: We chose to use real-world testing, as simulations are very time-consuming. Simulating one of these structures accurately can take hours or even days, so if we want to try to explore many structures to find those with the high performance, it is infeasible. Instead, we use real-world data as it allows us to test batches of structures much more quickly. Testing these batches is still costly, which is why using Bayesian optimization is key for exploring and exploiting the design space efficiently.

Q: What challenges did you encounter in integrating 3D printing, machine learning, and experimental testing into a single research workflow? Was one component more difficult to align than the others?

A: The structures were fabricated using specialized equipment in the MIT.nano lab capable of microscale printing. This made the project a collaboration between researchers in CSAIL and MechE engineers leveraging capabilities at MIT.nano. We couldn’t determine which structures to test next until we had results from the previous batch, so integrating the physical fabrication and testing processes with the computational work from CSAIL posed a significant logistical challenge. We had to rapidly coordinate between our sub-teams to exchange results and queue up new test batches in real time.

Q: Your team developed a dataset of over 270 physically validated metamaterials. Why is this kind of open resource important, and who do you hope uses it?

A: This kind of open resource is important because it allows others to build directly on our work. Physically validated microscale metamaterials are time-consuming and expensive to print and test, so sharing this dataset helps lower the barrier for other researchers and developers working on these structures in materials science, machine learning, and engineering. By making the dataset public, we hope to accelerate discovery and support a broader community in developing new methods and applications for these structures.

Fourteen fabricated micro-TPMS structures printed on a Nanoscribe 3D printer and tested using an Alemnis nanoindenter.

Image courtesy of the researchers

Q: You mention potential applications ranging from sports gear to medical implants to robotics. Is there a particular use case you’re especially excited about?

A: I’m especially excited about potential applications in healthcare because they have the power to directly improve people’s lives. Whether it’s high-performance implants or customized prosthetics, these kinds of technologies could have a meaningful impact on individual well-being.

Q: This was a highly collaborative project. Can you tell us a bit about the team behind it and how you worked together across disciplines?

A: Our team comprised of researchers at MIT CSAIL, who worked on the computational side of the project, and researchers in the Mechanical Engineering department, who worked on physical fabrication and testing. The project was very exciting in that it was an iterative experimental discovery project. The CSAIL group would send a batch of structures to the Mechanical Engineering group to print and test, and then based on those results, the CSAIL group would calculate the next best batch to test. Therefore, there were many moments where we were waiting to see how the newest batch of structures was performing, and it was very exciting in later batches when we got back structures with big performance boosts.

Q: The structures you discovered are beautiful, in addition to being functional. How do aesthetics and design thinking play into your work as an engineer?

A: I’ve always loved art and design, and painting and drawing have been a constant in my life. That creative background deeply shapes how I approach engineering. I often find myself drawn to the visual form of a structure, not just for its beauty, but because elegance in design often reflects underlying efficiency or harmony. Triply periodic surfaces combine function with striking mathematical beauty. Their symmetry and elegance are both visually compelling, but also connect with their material properties and functions. To me, aesthetics and engineering are deeply connected, and to me, beauty often signals that something is fundamentally well-structured and interesting to investigate.

Q: You were a 2025 Design Fellow at MAD. How does this project relate to your broader interests in design? Has your experience with MAD shaped how you approach this work?

A: I'm always drawn to research projects that involve a strong design component, in this case, designing and discovering new materials. Through the MAD Fellowship, I attended weekly lunches and seminars where I engaged with other fellows and learned about design concepts across a range of disciplines. These sessions were also a great opportunity to share my own work and ideas and receive valuable feedback from people outside of computer science.

Some of the other fellows were working on structural optimization, and seeing how they formalized and explored design spaces in their own work was both informative and inspiring. The MAD Fellowship also made me braver in my research, where I was more willing to try new directions and less afraid of failure.

Sometimes, spending too much time in one subfield can lead to a kind of tunnel vision, where you're focused only on a narrow set of questions or overly concerned with publication metrics. Being exposed to the diverse workflows and domains of the other fellows broadened my perspective and helped me think more critically about the broader impact and purpose of my own work. It’s also a very supportive and friendly community, and I am grateful for the friendship and moral support of both the MAD fellows and the MAD team throughout the last year.

Q: If you could scale this method beyond TPMS — what would you want to explore next?

A: I would love to use similar techniques to discover materials or structures that are biodegradable or eco-friendly. 3D printing is a wonderful technology that lends itself to doing mindful personalized fabrication rather than buying mass manufactured projects. However, it is also often an incredibly wasteful process, which can negate many of its potential environmental benefits. That means that at larger scales, 3D printing generates a lot of waste plastic that gets stuck in landfill for hundreds of years. I think a lot more work can be done in this area. One of the big questions for this problem is on what kinds of materials we use and what kinds of structures we print that generate less waste and less harmful waste.

Q: What advice would you give to students or early-career researchers trying to work across technical and design disciplines?

A: My best advice is to “go for it”. Interdisciplinary work can sometimes invite confusion or even criticism. I've had people question whether my work is “technical enough,” and others wonder if it’s too technical. But these tensions are often a sign that you're working in a space where something new and exciting can happen.

I’m now entering my third year of my PhD, where I’m starting to define a focused research agenda at the intersection of computational fabrication, graphics, and HCI. But getting here has involved a winding path through projects in robotics, computer vision, ML, graphics, and design. These diverse research experiences have been incredibly valuable to my growth. Over time, the “activation energy” needed to dive into a new domain or unfamiliar algorithm has gotten lower, simply because I’ve been exposed to a wide range of tools, methods, and mindsets.

Many of those projects came from simply saying “yes” to opportunities that excited me, even if I wasn’t an expert in that area. If opportunities don’t come to you, go find them. Volunteer in a lab or on a project that sparks your curiosity, even if it’s outside your comfort zone. Having this foundation can really help you later on when it is time to start diving deep into a particular algorithm or method, as it opens your eyes to different ways of going about solving a problem.

Another important point is that when working across disciplines, it’s crucial to stay flexible and open to different ways of thinking. What counts as impactful research can vary a lot on the reader, so talk to people outside your area to learn more about what matters in their eyes. Ask questions, get feedback, and share your work often. Unique and new ideas often emerge at the intersection of different perspectives, and those conversations are where I find some of the most exciting work can start to happen.

Apr 24, 2024

Aug 4, 2023

May 2, 2024