Concrete Printed Bridge

About

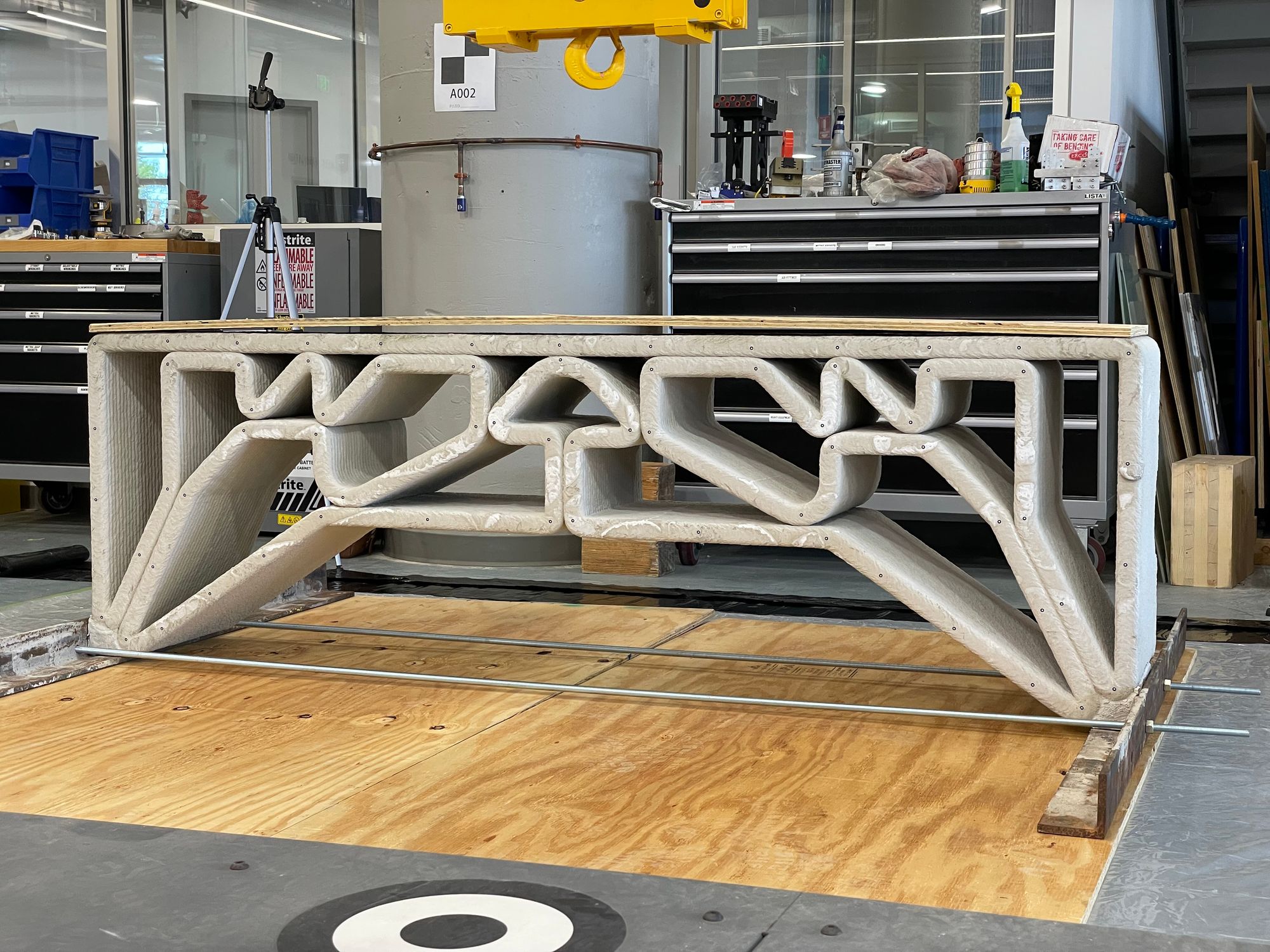

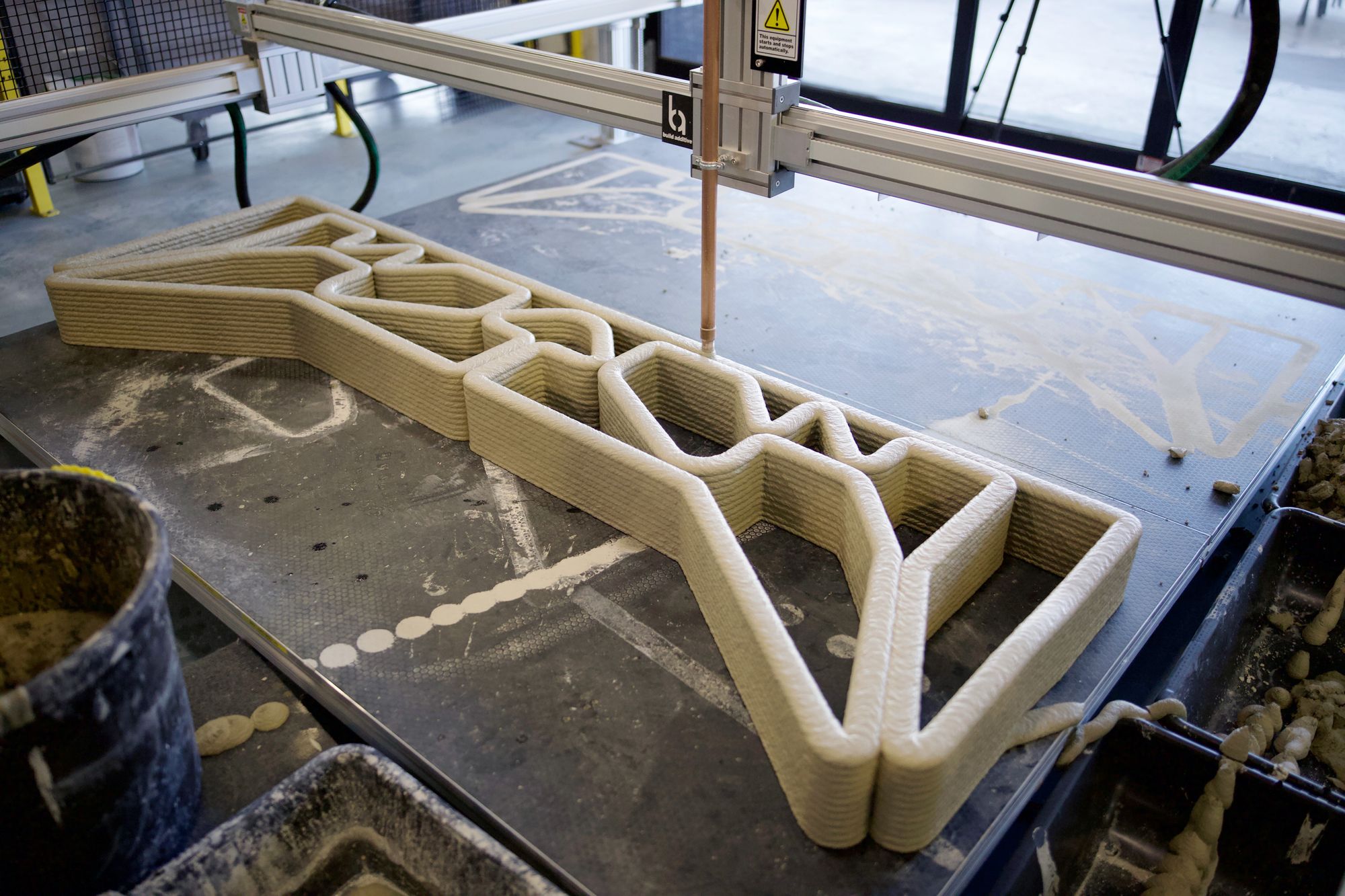

2024 Design Fellow Zane Schemmer and Hajin Kim-Tackowiak, PhD candidates in the Carstensen Group, are optimizing new ways to design concrete structures considering construction methods. Computational work was experimentally validated through the building and testing of a small-scale 3D-printed concrete bridge. The bridge was loaded with 2,000 lbs.

Solution & Impact

The design solution creates an all-compression concrete bridge that can be 3D-printed in one continuous motion without lifting up the print head. The design respects material constraints and constructability constraints that are critical for additive manufacturing. This work impacts the way designers create new structures that leverage the advantages and disadvantages of new construction technologies.

Features

- Minimizes embodied carbon (environmental impact) of structure.

- Generates desgins that greatly improve constructability considering old and new manufacturing techniques.

- Allows complex problems to be approached by a wider range of designers.